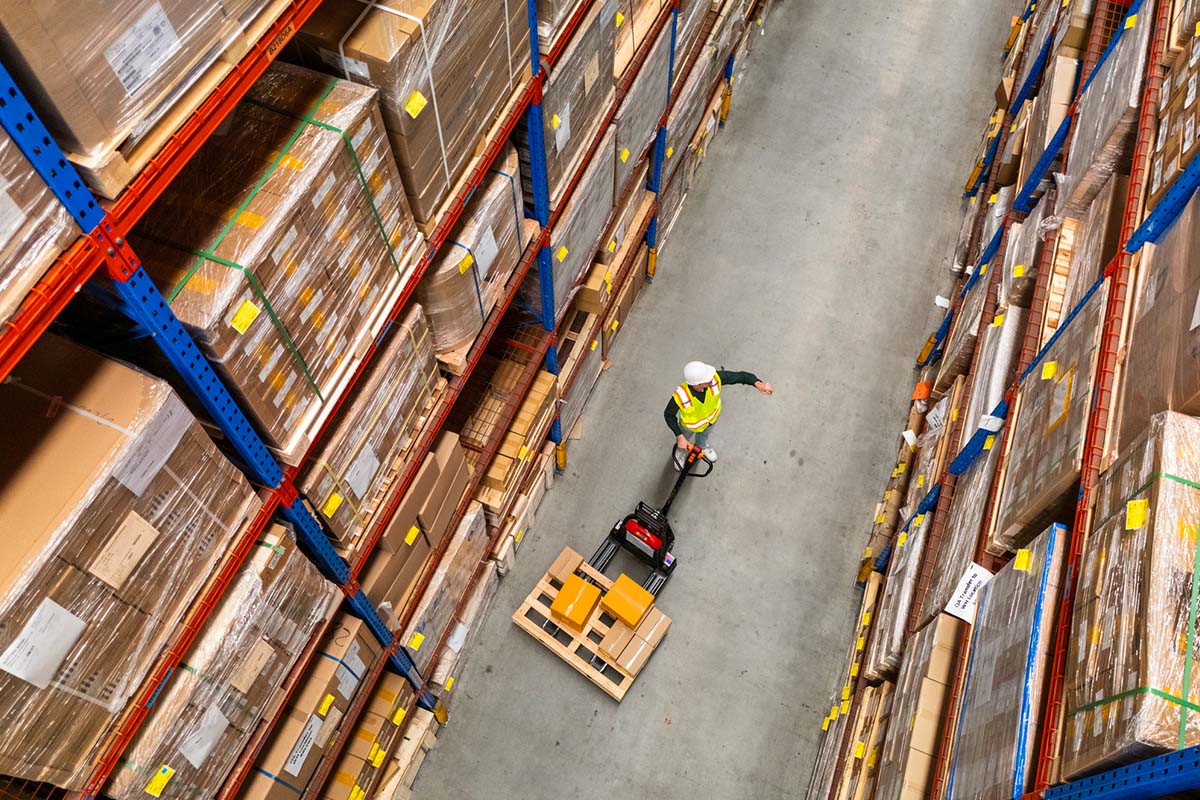

Out-of-control inventories.

Inefficient changeovers.

Spiraling material costs.

Aprio helps manufacturers Account for Anything™

Operational challenges can chip away at profits, slow production, and create bottlenecks that ripple across your entire business.

But with Aprio as your partner, you’ll be able to proactively identify those friction points and prioritize high-impact improvements for strengthening throughput, optimizing inventory, and elevating your overall performance.

By combining data-driven operational analysis with practical process enhancements—from KPI-driven dashboards to supplier and procurement strategies—our specialists help companies turn operational insights into measurable results that drive sustainable growth.